Innovations in Heat Flux Measurement: The Future of Water-Cooled Sensor Technology

Innovations in Heat Flux Measurement: The Future of Water-Cooled Sensor Technology

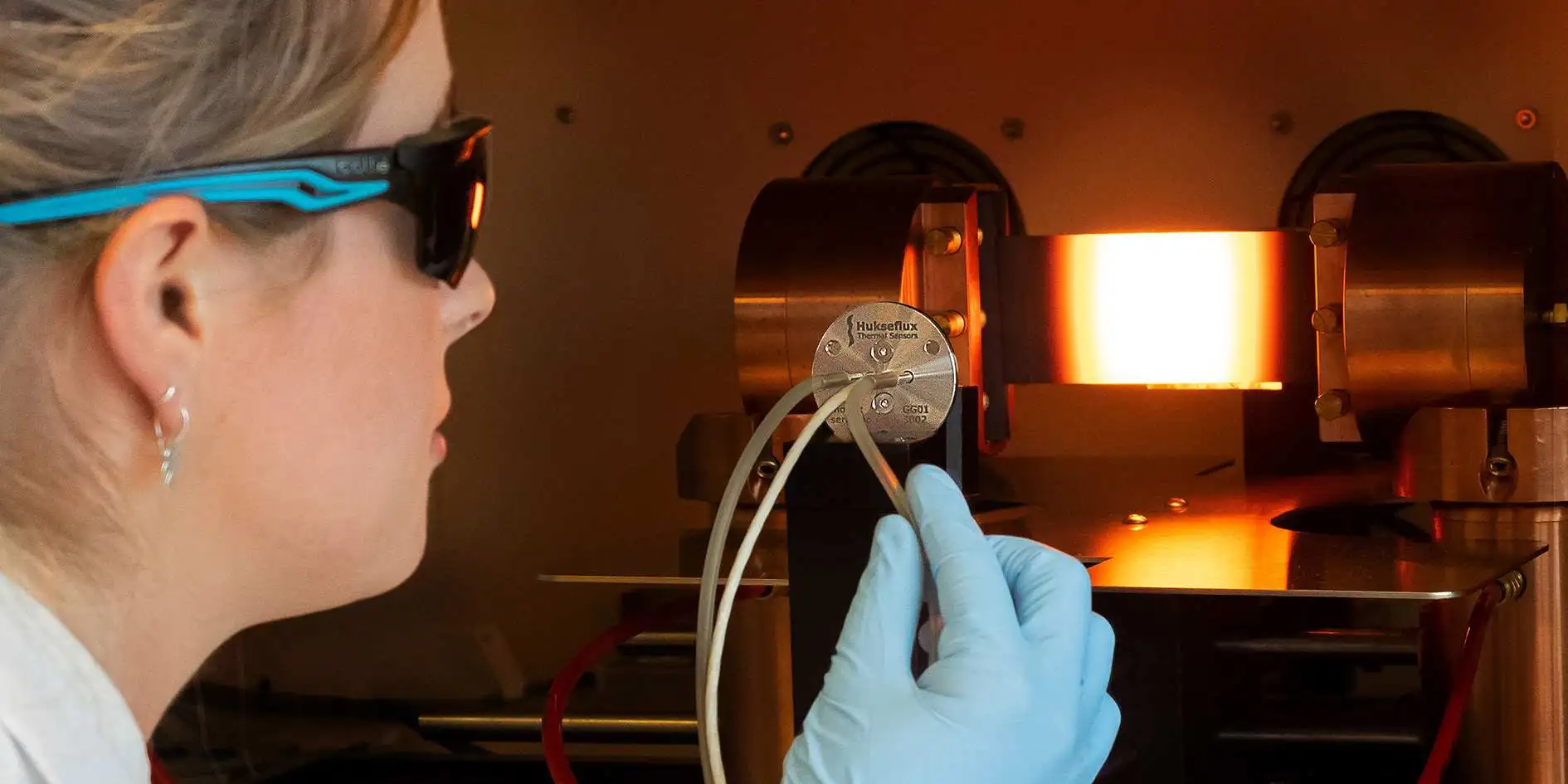

Water-cooled heat flux sensors have become essential for accurately measuring thermal energy transfer in high-temperature applications such as combustion research, aerospace testing, and industrial manufacturing. These sensors—often designed with Schmidt-Boelter and Gardon gauge technologies—use water cooling to protect the sensing element from extreme heat, enabling precise data collection under harsh thermal conditions. As technology advances, new innovations in design, materials, and data analysis are transforming the way we measure and interpret heat flux.

1. Advanced Materials and Miniaturization

Ongoing research into high-temperature alloys, ceramics, and composite materials is leading to more resilient sensor housings and sensitive elements. These advanced materials can better withstand thermal shock, chemical corrosion, and mechanical stress, thereby extending sensor life and reducing the need for frequent recalibration. Additionally, miniaturized sensor designs allow for higher spatial resolution and faster response times, opening up new applications in confined or complex environments.

2. Integrated Cooling Systems

Future designs are expected to feature adaptive water flow control systems that adjust the coolant flow in real time based on fluctuating thermal loads. This smart cooling approach maintains optimal sensor operating conditions even under rapidly changing heat flux levels. In some cases, hybrid cooling methods—combining water cooling with air or phase-change materials—are being developed to further enhance sensor resilience in ultra-high-temperature environments.

3. Smart Sensors and Real-Time Analytics

Advancements in microelectronics now allow for the integration of embedded data processing and communication modules directly within the sensor. These “smart sensors” can perform on-board signal conditioning, self-diagnostics, and even transmit data via IoT networks. For example, sensors used in water-cooled heat flux sensor calibration benefit from real-time analytics that ensure high-quality data and proactive maintenance alerts. (Learn more about our water-cooled sensor calibration services here: Water-Cooled Heat Flux Sensor Calibration.)

4. Machine Learning and Predictive Modeling

By applying machine learning algorithms to historical calibration and operational data, engineers can predict sensor drift and schedule recalibrations more efficiently. Data fusion techniques are also emerging that combine inputs from multiple sensors to generate a comprehensive thermal profile. This approach can significantly improve process optimization in applications such as aerospace testing and industrial process monitoring.

5. Enhanced Calibration Techniques

Innovations in calibration are a critical part of advancing water-cooled sensor technology. Automated calibration systems with robotic handling reduce human error and speed up the process, ensuring reproducibility. Additionally, calibration environments are increasingly able to simulate real-world conditions, including variable coolant flow and dynamic temperature changes. For a deeper dive into calibration standards, check out our Essential Guide to Calibration Lab Standards.

6. Novel Applications on the Horizon

The evolution of water-cooled heat flux sensors is opening new opportunities across multiple industries. In aerospace, these sensors will be critical for characterizing extreme thermal loads in hypersonic flight and space exploration. In manufacturing, particularly in automated processes and metal additive manufacturing, real-time heat flux monitoring can help optimize product quality and energy efficiency. To explore broader applications of thermal measurement, visit our blog.

7. Collaboration and Standardization

As industries push the boundaries of high-temperature operations, collaboration among manufacturers, calibration laboratories, and end users is becoming increasingly important. Standardization efforts by organizations such as ASTM, IEC, and ISO ensure that new sensor technologies and calibration methods meet stringent performance criteria. For additional insights on calibration and measurement standards, read our article on Comparing Calibration Standards.

Conclusion

The future of water-cooled heat flux sensor technology lies in the integration of advanced materials, adaptive cooling strategies, and intelligent data processing. These innovations promise enhanced reliability, faster response times, and expanded applications across industries such as aerospace, manufacturing, and energy. By embracing cutting-edge calibration techniques and smart sensor features, researchers and industry professionals can unlock deeper insights into thermal phenomena, optimize processes, and drive safer, more efficient solutions in extreme heat environments.

To learn more about our calibration services and how we can support your high-temperature measurement needs, visit our Radiometer Calibration Services page or contact us.